recamic background

Runderneuerte Reifen von RECAMIC, empfohlen von Michelin

Ein umfangreiches Angebot an runderneuerten Reifen aus vorgefertigten Laufstreifen, die für alle Einsätze geeignet sind, unabhängig von Karkasstyp oder Hersteller.

Was zeichnet eine RECAMIC Runderneuerung von Michelin aus?

- Lauffläche: Die RECAMIC Profile haben ähnliche Eigenschaften wie die Profile der MICHELIN Neureifen. RECAMIC Laufstreifen werden aus von Michelin hergestellten Gummimischungen gefertigt. Sie sind damit für die gleichen Einsätze konzipiert wie die jeweiligen MICHELIN Neureifen und ermöglichen eine optimierte Laufleistung.

- Prozess: Ein standardisierter Prozess stellt sicher, dass die Runderneuerung beginnend von der Karkassprüfung bis zur Endkontrolle nach dem RECAMIC Prozess durchgeführt wird. Dieser Prozess sichert die Qualität der ausgewählten Karkassen und den daraus produzierten RECAMIC Reifen.

- Geschultes Personal: Das RECAMIC Team führt in den Runderneuerungswerken ein umfangreiches Schulungsprogramm durch. Jeder Anwender wird in den RECAMIC Spezifikationen und Arbeitsmethoden geschult und zertifiziert

- Qualität und Zuverlässigkeit: Strenge Qualitätskontrollen durch regelmäßige Audits stellt sicher, dass die Qualitätsstandards jedes zertifizierten RECAMIC Runderneuerungswerks eingehalten werden.

- Zuverlässiger runderneuerter Reifen: Durch umfangreiche Schulungen, Qualitätskontrollen und konsequente Anwendung des RECAMIC Prozesses erhalten die Kunden einen gleichbleibend hochwertigen RECAMIC Reifen.

Um dieses Video anzusehen, müssten Sie einige Cookies von YouTube akzeptieren. Klicken Sie einfach auf die Schaltfläche unten, um das Cookie-Modul zu öffnen.

YouTube-Cookies akzeptierenÜberzeugte Kunden berichten

recamic barth testimonial

»Von unseren Fahrern erhalten wir ausschliesslich positives Feedback.«

Stefan Heckhoff, barth Spedition GmbH

»Wir haben mit MICHELIN und RECAMIC einfach eine ganzheitliche Lösung gefunden.«

Harald Eichhorn, Eichhorn AG

eichhorn bild testimonial

Welches sind die Vorteile der RECAMIC Runderneuerung?

Die aufgearbeitete Karkasse wird mit einem vorgefertigten Laufstreifen im Wunschprofil versehen. Bei der anchließendem Vulkanisation im Autoklaven bei 115°C für etwa drei Stunden wird die dauerhafte Verbindung zwischen Laufstreifen und Karkasse hergestellt.

Die Vorteile der RECAMIC Runderneuerung:

Wirtschaftlich

- Ähnliche Leistung wie bei Premium-Neureifen

- Niedrige Kosten pro Kilometer

- Optimierte Balance zwischen Laufleistung, Grip und Kraftstoffverbrauch

Zuverlässig

- Hohe Standards bei der Runderneuerung und konstante Qualität des Reifens

- Von Michelin zertifizierte Runderneuerungswerke und -prozesse

- Hochwertige Laufstreifen, von Michelin hergestellt

Umweltfreundlich

- Einsparung von Rohstoffen

- Weniger Altreifen

2

rec 3

RECAMIC SORTIMENT

Von Michelin entwickelte Profile, geeignet für alle Einsätze

long distance logo

FERNVERKEHR

- Große Entfernungen, auf Autobahnen und Fernstraßen

- Wenig Beschleunigen und Bremsen

NAH- UND FERNVERKEHR

- Große und mittlere Entfernungen, auf Land- und Fernstraßen mit häufigem Anfahren und Bremsen

- Kurze Strecken mit vielen Be- und Entladestellen

- Zufahrt zu Be- und Entladestellen auf wenig aggressivem Untergrund

- Schwierige Wetterbedingungen (Regen, Schnee, Eis)

regional logo 2

worksite logo

STRASSE/BAUSTELLE

- Vorwiegend kurze Strecken auf unterschiedlichsten Straßen

- Anfahrt zu Be- und Entladestellen in schwierigem, teilweise unbefestigtem Gelände

BUSSE IM NAH-/REISEVERKEHR

- Große und mittlere Entfernungen, von Autobahnen bis hin zu Landstraßen, teilweise mit häufigem Anfahren und Bremsen

- Kurze Strecken mit häufigem Anfahren, Bremsen und Rangieren

intercity logo 3

urban logo

KOMMUNALVERKEHR

- Fahrten vorwiegend im Stadtgebiet mit häufigem Anfahrenund Bremsen (Stadt- und Linienbusse, Müllfahrzeuge, Straßenreinigungsfahrzeuge usw.)

Detaillierte Informationen zur Förderfähigkeit von MICHELIN Lkw-Reifen finden Sie in den beigefügten Dokumenten:

Übersicht der Informationen zur Förderung

Übersicht der förderfähigen Lkw-Reifen

RECAMIC, exklusive Lösungen

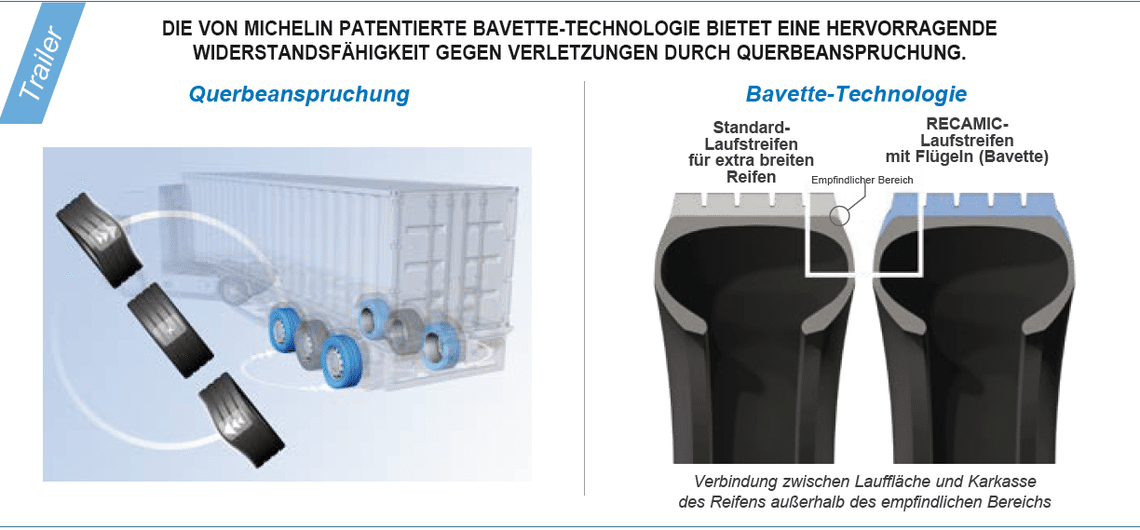

Bavette-Technologie

bavette technologie

Eine hervorragende Widerstandsfähigkeit gegen Verletzungen durch Querbeanspruchung, speziell für Trailerachsen.

1. Die Bavette-Technologie trägt zur Vermeidung von Einrissen im Schulterbereich bei

2. Am Rand der Lauffläche sich verjüngendes Gummi (Flügel):

- Passt sich perfekt der Karkassenform an

- Verringerung von Lufteinschlüssen bzw. Einrissen im Schulterbereich

3. Längere Flügel:

- Verteilung der Scherkräfte durch das Querschrubben

- Verbesserte Optik

11

12

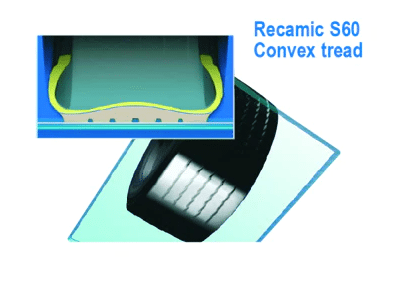

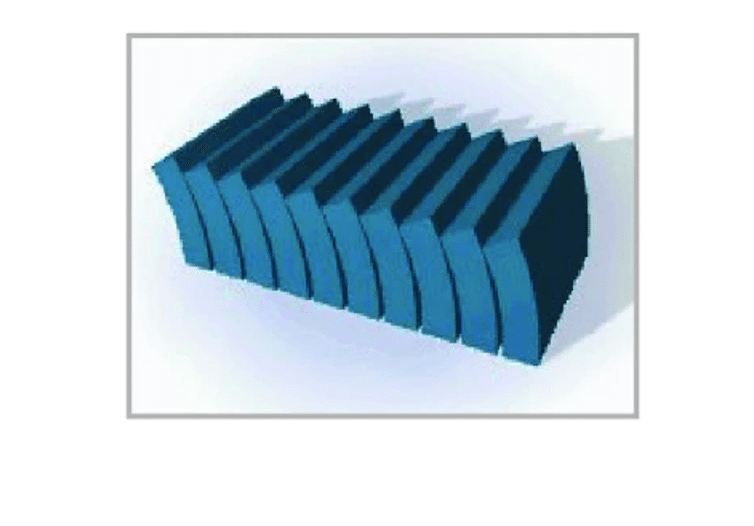

Die Serie 60

Reduziert die Erwärmung und erhöhten Verschleiß im Schulterbereich.

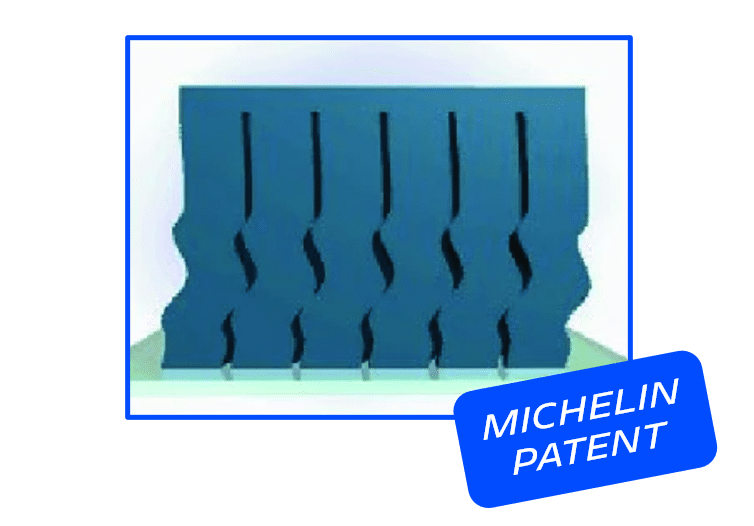

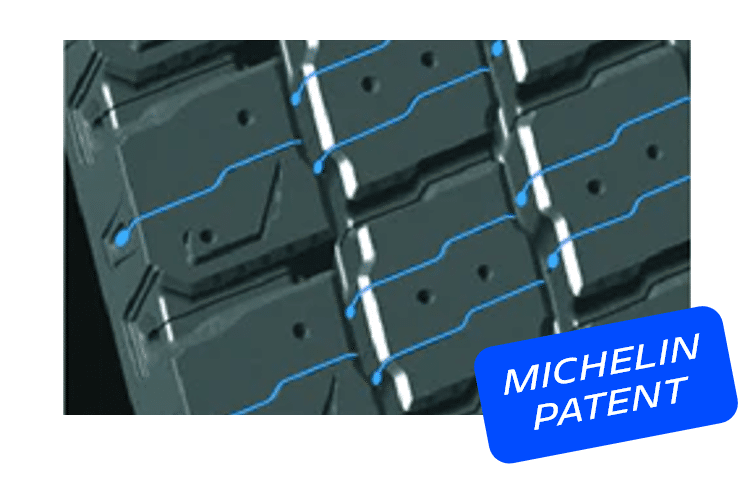

Dreidimensionale Lamellen

Lamellenblöcke verformen sich beim Beschleunigen oder Bremsen. Durch die Verformung von Standardlamellen reduziert sich die Kontaktfläche des Reifens auf der Straße. Dieser Effekt wird mit Dreidimensionalen Lamellen stark reduziert: Sie verringern die Ursachen für unregelmäßigen Verschleiß erheblich und verlängern die Nutzungsdauer des Reifens.

Dreidimensionale Lamellen

recamic dreidimensionale lamellen

Standardlamellen

recamic standardlamellen

tread pattern 2

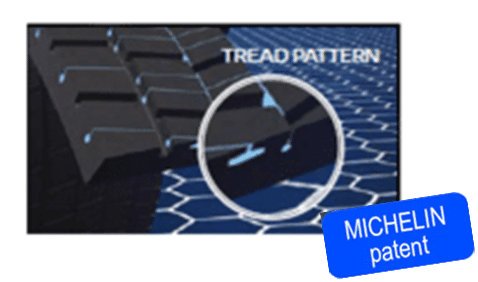

Regenion

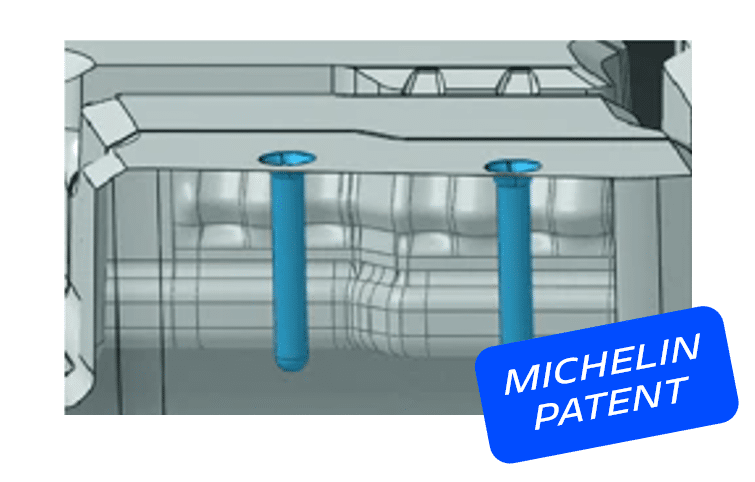

Selbstregenerierende Profilblöcke, gestützt durch unser 3D-Metalldruckverfahren, bieten eine solide Bodenhaftung über die gesamte Lebensdauer des Reifens und bei allen Wetter- und Einsatzbedingungen.

recamic wassertropfenlamellen

Wassertropfenlamellen

Sie haben eine Wassertropfenform und kommen im Laufe der Abnutzung des Profils zum Vorschein und bilden so neue Kanten und Rillen. Sie verleihen dem abgenutzten Reifen optimierten Grip.

recamic stablamellen

Stablamellen

- Für verbesserte Haftung auf rutschiger Fahrbahn

- Die Lamellen haben eine zylindrische Form und nehmen auf der Fahrbahn stehendes Wasser auf

Falls Sie weitere Informationen erhalten möchten oder Fragen zu RECAMIC haben, schreiben Sie uns!